Probe cleaning

sonicclean

usePAT´s ultrasonic cleaning system keeps your on- and inline probes clean. The automatic removal of organic and inorganic fouling on sensors is possible in various industrial liquids and ensures optimal process monitoring.

This effect helps to prevent measurement drifts, allowing your probes to deliver continous accurate measurements in real time. This allows you to optimize your work and production processes and save time and resources.

Enable your probe to measure reliable

usePAT mainly uses ultrasonic waves in the megahertz range. These clean your probes gently and safely. This allows cleaning in the sensor's measuring range during the ongoing process.

All systems are designed in-house and manufactured to fit your probes.

Operating principle of sonicclean

The ultrasound emitted by sonicclean gently pulls particles away from the surface of the measuring window of a probe in order to keep it constantly and automatically clean.

Advantages of sonicclean

Automatic cleaning keeps probes constantly clean

Efficiently removes organic and inorganic fouling

Improves workers´ safety and saves resources

Application examples

Wastewater (O2)

Sensor type: oxygen sensor

Coating: Biofilm

Product: sonicclean+

Klagenfurt wastewater treatment plant (AUT)

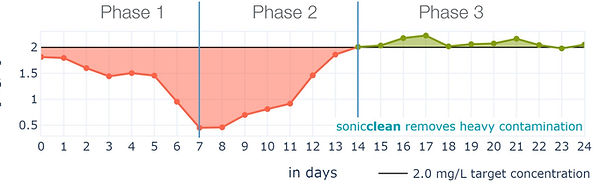

The following graph shows the measured oxygen in mg/L at a municipal wastewater treatment plant in Klagenfurt, Austria

(300,000 population equivalent). The target value for aeration is 2.0 mg/L.

A second probe, which was continuously cleaned by hand, was also used to validate the values of the ultrasonically cleaned probe.

sonicclean uses ultrasound to keep the oxygen probe constantly clean in the aeration tank, thus enabling optimal process control (aeration).

Phase 1

Without sonicclean+, the sensor begins to clog measurably after a few days (contamination begins on day 7). The measured oxygen value drops from 2 mg/L to 0.5 mg/L

Phase 2

The ultrasound of the sonicclean+ is activated. The sensor gradually becomes clean and, over time, measures values that correspond to the actual condition of the wastewater.

Phase 3

The sonicclean+ keeps the probe now continuously clean – no new contamination occurs. This ensures that measurements are not compromised by deposits.

Wastewater (UV-Vis)

Sensor type: UV-Vis probe

Coating: Biofilm

Product: sonicclean

Verden wastewater treatment plant (DE)

The Verden wastewater treatment plant successfully uses the ultrasonic cleaning system sonicclean during its operations.

The plant receives both municipal and industrial wastewater, resulting in stubborn organic fouling on the measuring probes. Manual cleaning has previously been time-consuming and resource-intensive.

sonicclean is used in combination with several probes in Verden:

-

Oxygen probe in the aeration

-

Conductivity sensor in the drain

-

UV-VIS or SAK probe in the drain

Ultrasonic cleaning reliably removes fouling without mechanical stress on the various inline probes – automatically and permanently.

Wastewater (AN-ISE)

Sensor type: Ammonium-Nitrate (AN-ISE)

Coating: Biofilm

Product: sonicclean

Korneuburg wastewater treatment plant (AUT)

The wastewater treatment plant of the Korneuburg Wastewater Association wants to save energy for aeration. In order to do this, its AN-ISE probes in the aeration tank must always deliver reliable measurements and therefore be manually cleaned of fouling on a regular basis — a time-consuming process.

With the installation of the automatic ultrasonic cleaning system sonicclean, the probe is now kept automatically clean. This makes the measurements more stable and precise, and now reliably displays accurate daily trends.

This reduces the workload for employees, who can now use the time for other tasks. In addition, the consistently accurate measurement data increases the efficiency of the aeration system, thereby avoiding unnecessary costs.

Food (pH)

Sensor type: pH probe

Coating: Fruit sugar

Product: sonicclean

Cleaning a glass pH electrode that was contaminated with a fructose coating.

The graphic shows an inline pH probe measuring a water pH of 7. Shortly after the contaminant is applied, the pH drops below 5 (starting at 2:15 minutes). After switching on usePAT´s opposite add-on, the ultrasound gently removes the organic coating (starting at 2:30 minutes). Within 5 minutes, the probe is clean again and measures the correct pH of 7 (starting at 7:30 minutes).

Pharma (inline microscope)

Sensor type: inline microscope

Coating: Glycine crystals

Product: sonicclean+

During production, crystals stick to the inline microscope, making live monitoring difficult.

The video shows a liquid in which glycine crystals are forming (at 200 rpm). For real-time monitoring of the process, an inline microscope is used, to which the crystals adhere. These are gently pulled away from the probe lens using ultrasound, enabling optimal process control by keeping the probe window clean.

Biotechnology (FBRM probe)

Sensor type: FBRM probe

Coating: grown yeast cells

Product: sonicclean+

A biofilm consisting of fermented yeast cells is applied to a focused beam reflectance (FBRM) probe. The probe allows for quantification of window fouling using the so-called fouling index.

The graph shows the successful cleaning which is achieved by using sonicclean+. After activating the ultrasound (from approximately 2:14 minutes), the fouling index (FI) was reduced to zero within a few minutes (from approximately 2:16 minutes).

Biotechnology (turbidity probe)

Sensor type: Turbidity probe

Coating: Algae

Product: sonicclean

Spirulix, part of Rohkraft GmbH, produces algae for the production of everything from muesli and pasta to pure dietary supplements in Reidling (Austria).

At Spirulix, usePAT is cleaning an inline turbidity probe in a tank full of algae (spirulina). The sonicclean automatically keeps the probe clean to ensure precise real-time data for live monitoring of algae growth and thus algae production.