Inline quality control

soniccatch

soniccatch enables innovative applications in the field of process analytics. It uses ultrasonic fields to capture particles in flowing industrial fluids.

In this way, particles are presented in front of the probe, enabling precise inline measurements in real time directly in the process. This novel approach supports industry in generating valuable inline data and minimizing time-consuming sampling.

Enable your probe to reach its full

potential

.png)

Ultrasound is mainly used in the megahertz (MHz) range, allowing it to gently capture crystals or living cells for measurement. This enables highly detailed quality monitoring through regular and precise measurements.

All systems are designed in-house and manufactured to fit your probes.

Operating principle soniccatch

Using ultrasonic forces, soniccatch captures and holds passing particles in a suspension in the measuring area of an inline probe. This creates a kind of inline sample that allows the probe to measure it with enough time – for optimal quality control.

Advantages of the soniccatch

Creation of inline samples in real time

Reliable live monitoring

Continuous process and quality control

Reduced sampling and potential safety risks

Application examples

Chemistry & Pharma

Probe type: inline microscope with spectroscopy probes

Particles: Crystals

Product: soniccatch&clean

soniccatch&clean is an innovative solution for optimizing inline measurements in crystallization processes. Crystallization is one of the most important techniques in chemistry and is used in many industries as a separation and purification process. The quality of this process has a decisive influence on product properties such as purity, stability, solubility, bioavailability, and morphology.

The soniccatch&clean enables two major improvements:

1. Particle control for improved sensitivity

When combined with inline microscopes, soniccatch captures crystals in the probe's focal plane, increasing the number of visible particles and thus enhancing the Raman probe's measurement signal. This improves the detection of crystal structures, especially at the beginning of crystallization.

2. Improving selectivity through inline cleaning

ATR/FTIR probes are only sensitive a few micrometers above the probe tip. This zone is often blocked by crystals, resulting in inaccurate spectra. soniccatch&clean can remove interfering crystals from the probe in a controlled manner. This cleaning mode prevents crystals from sticking to the probe window and allows for stable measurement signals in real time, even under high solid loads. This enables optimal inline quality control in continuous processes.

Advantages of soniccatch&clean:

Optimizing the measurement accuracy of probes

continuous accurate real-time process monitoring of the ongoing process

increased signal intensity of the measurement

improved stability through inline cleaning

This leads to optimised process control in terms of energy efficiency, resource conservation and yield.

Biotechnology

Probe type: Raman Probe

Particles: Yeast cells

Product: soniccatch

Process control in biotechnological production has traditionally relied on indirect parameters such as temperature, pH value, and sample analysis from the reactor. However, these data only correlate indirectly with the performance of the microorganisms. A better approach would be to measure the main components of the culture medium that are directly involved in the metabolism of the microorganisms, or to measure the cells themselves.

Spectroscopic instruments based on vibrational spectroscopy, such as Raman or ATR/FTIR, provide selective chemical information through non-destructive measurements. However, they suffer from low sensitivity for cell measurements. This is where ultrasonic particle manipulation comes in: The soniccatch system uses standing ultrasonic waves to gently position particles in a targeted manner and keep them in the focus area of the Raman probe. This enables a type of inline sampling with simultaneous measurement of the relevant cells or components of the liquid phase with increased sensitivity and selectivity.

Example: yeast fermentation:

A 5-liter bioreactor is equipped with a Raman probe that has been integrated into the soniccatch fitting. Precise control of the ultrasonic field is used to bring the cells into the desired position in front of the measuring window of the spectroscopic probe (in the gap between the probe and the add-on).

The combination of Raman spectroscopy and soniccatch enables selective measurement of the fermentation medium. Partial Least Squares (PLS) modeling can be used to determine important parameters such as glucose, ethanol, and biomass concentration.

When soniccatch is activated, the cells are captured and measured in the focus area of the probe to obtain representative spectra. The complex spectral fingerprints of proteins, lipids, and carbohydrates contain in-depth information about the physiological state of the cells.

Principal component analysis (PCA) is then used to clearly distinguish between spectra of cells from different fermentation phases. Without the need to measure critical process parameters via sampling, it is now possible to directly monitor the active fermentation culture inline, including its control.

-

Growth phase of yeast cells

-

Metabolic change (diauxic phase)

-

Ethanol is consumed (respiration phase)

-

Dormant state (hibernation)

soniccatch is available as an add-on for most inline probes. The use of ultrasonic fields enables increased sensitivity, selectivity, and stability of the inline measurement signal for various processes.

The soniccatch system is available as an add-on for most inline probes. The use of ultrasonic fields enables increased sensitivity, selectivity, and stability of the inline measurement signal for various processes.

Environment

Probe type: Raman Probe

Particles: Mikroplastic

Product: soniccatch

Microplastic particles are a global environmental problem. These plastic particles, which are smaller than 5 mm, have spread throughout all oceans, the air, and food. Conventional detection methods require time-consuming filtration of large volumes of water, followed by e.g. Raman spectroscopy analyses in the laboratory. These methods are slow, prone to contamination, and exhibit variable sensitivity for the smallest particles.

soniccatch offers a new method for direct microplastic detection that does not require sample preparation. As an example, 3.4 μm poly(methyl methacrylate) (PMMA) microspheres with a concentration of 90 ppm were stirred into water. A soniccatch system in combination with a Raman probe was used for inline measurement.

To perform the measurement, the probe is inserted into the ultrasonic fitting. The ultrasonic field generated between the probe head and the fitting's signal transmitter captures the particles at the nodes of the standing wave, which overlaps with the focus of the Raman probe. The microplastic particles captured in this way remain in the probe's measuring range long enough for it to record a detailed spectrum of the plastic type.

The ultrasound technique shows impressive results:

-

At least 1500-fold signal amplification of the PMMA Raman signal

-

Fast detection: A clear signal was distinguishable after 5 minutes

Ultrasound-based microplastic detection represents a promising approach to environmental monitoring and can contribute to the urgently needed standardization of inline microplastic monitoring.

Key advantages of the method:

-

No sample preparation required

-

Analysis time reduced from hours to minutes

-

Contamination-free thanks to direct inline measurement and analysis

-

Portable application for field measurements possible

Biotech

Probe type: Mid ATR Probe

Particles: Cyanobacteria

Product: soniccatch

As an alternative to conventional plastic, manufacturers are researching the production of bioplastics. One example of this is polyhydroxybutyrate (PHB), a biodegradable plastic produced by cyanobacteria from CO₂ and light, making it a sustainable alternative to petroleum-based plastics.

The biggest challenge in industrial PHB production is the difficult upscaling of photobioreactors, as light, nutrient, and CO₂ availability vary greatly. Therefore, rapid in situ analysis technologies are essential for process monitoring.

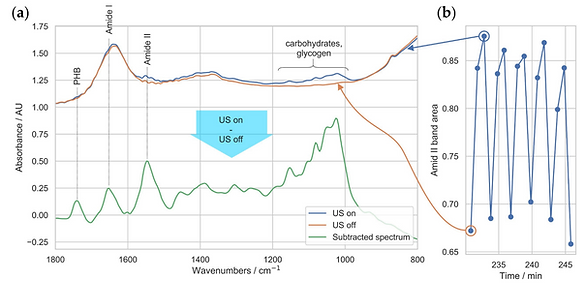

An innovative method for real-time monitoring of PHB production in photobioreactors uses a combination of ATR-FTIR spectroscopy and ultrasonic particle manipulation. The latter generates ultrasonic standing wave fields to trap cyanobacteria (Synechocystis sp. PCC 6714) cells directly in the bioreactor and hold them specifically to the ATR diamond surface of the inline probe. By alternating ultrasonic frequencies, pure cell spectra or pure spectra of the medium can be obtained.

Cyanobacteria were cultivated in 5.4-liter photobioreactors under nitrogen-limiting conditions. A biomass growth phase was followed by a PHB production phase, which was continuously monitored inline using soniccatch.

The results show successful inline quantification of PHB and glycogen with high accuracy. The characteristic PHB band at 1738 cm⁻¹ correlated well with offline reference measurements of extracted samples. The maximum PHB content reached 132 mg·g⁻¹ (13.2% of dry weight).

The ultrasound-enhanced ATR-FTIR measurement was performed continuously using a four-step protocol:

Capture cells, press them into the evanescent field, pull them away, and release them. By subtracting the spectra in different states, pure cell spectra are obtained.

This solution offers a fast, non-destructive alternative to time-consuming offline analysis methods involving toxic chemicals. The method also shows great potential as a process analytical tool (PAT) for monitoring and controlling biotechnological production processes, which contributes to the optimization of industrial PHB production.